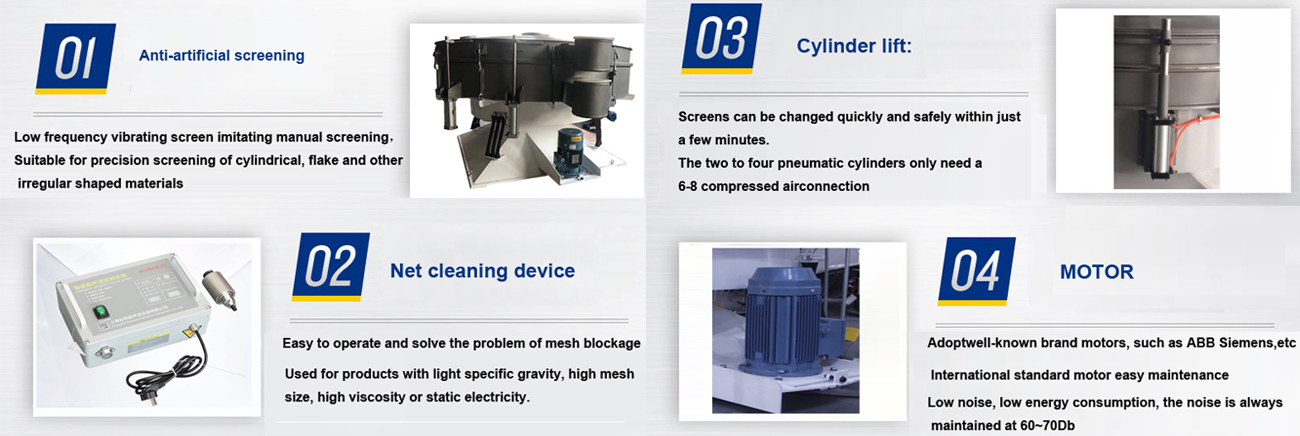

| Model | Effective area | Effective screen diameter | layers | Motor Power | Related dimensions | cleaning system |

| JX-CYBS-112 | 1.13 | 1250 | 1--5 | 2.2kw | 1250*1110 | bouncing ball drum brush ultrasonic |

| JX-CYBS-116 | 1.83 | 1580 | 1--5 | 3kw | 1580/1400 | |

| JX-CYBS-118 | 2.43 | 1778 | 1--5 | 3kw | 1778/1412 | |

| JX-CYBS-120 | 2.63 | 1880 | 1--5 | 4kw | 1880/1800 | |

| JX-CYBS-126 | 5.3 | 2560 | 1--5 | 5.5kw | 2650/1900 |

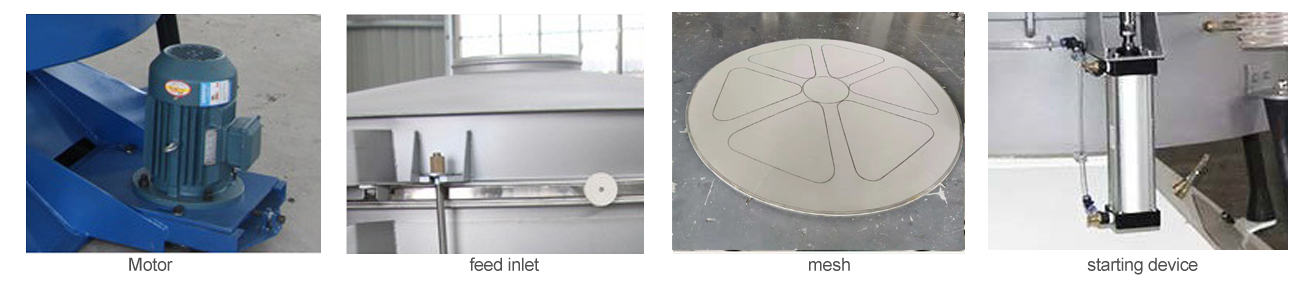

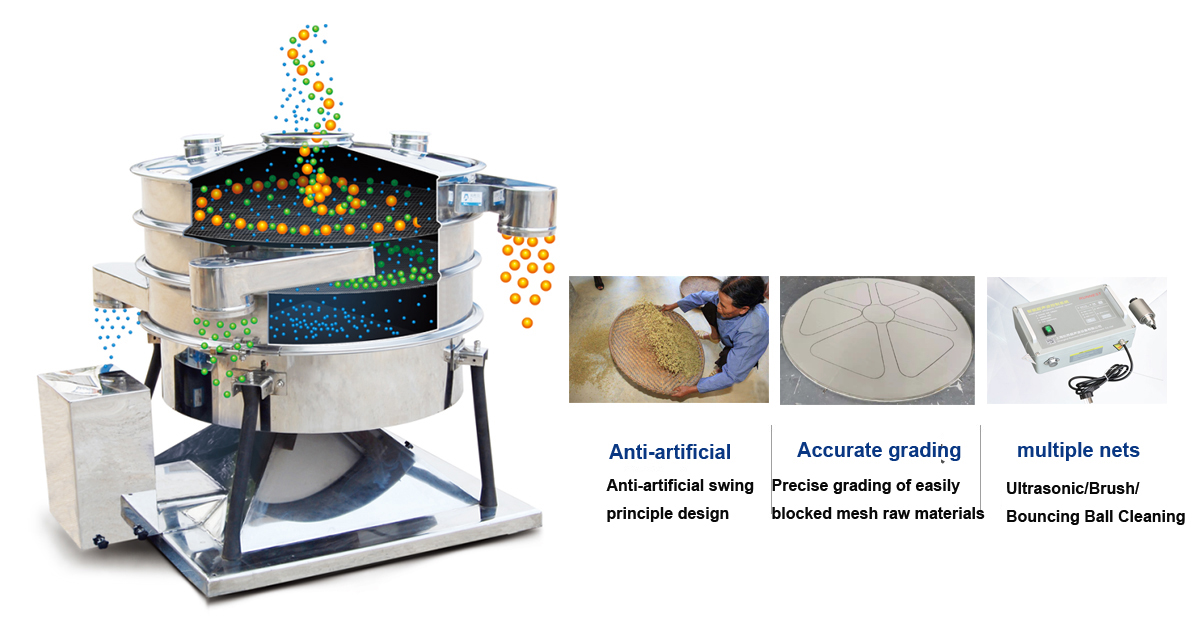

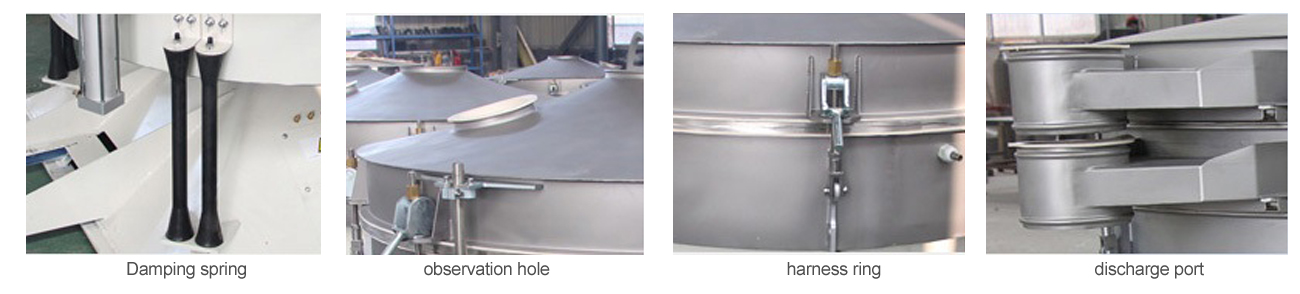

Ultrasonic swing sieve is a kind of low-frequency swing sieve that imitates artificial shaking. The vibrator produces nonlinear three-dimensional motion, and the material also produces the same motion similar to manual operation, so as to achieve the purpose of screening, and with the screening accessories, a more ideal screening effect can be obtained; suitable for round, cylindrical, sheet It can be used for materials that are easy to block and need to be precisely screened.Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry Application material Ultrasonic swing sieve is widely used in chemical, pharmaceutical, food and spices, tea, feed, plastic, rubber, fertilizer, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin and other industries to polarize fine materials and other operations.

Ultrasonic swing sieve is a kind of low-frequency swing sieve that imitates artificial shaking. The vibrator produces nonlinear three-dimensional motion, and the material also produces the same motion similar to manual operation, so as to achieve the purpose of screening, and with the screening accessories, a more ideal screening effect can be obtained; suitable for round, cylindrical, sheet It can be used for materials that are easy to block and need to be precisely screened.Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry Application material Ultrasonic swing sieve is widely used in chemical, pharmaceutical, food and spices, tea, feed, plastic, rubber, fertilizer, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin and other industries to polarize fine materials and other operations.